Supply Chain Mapping - visualise your supply chain

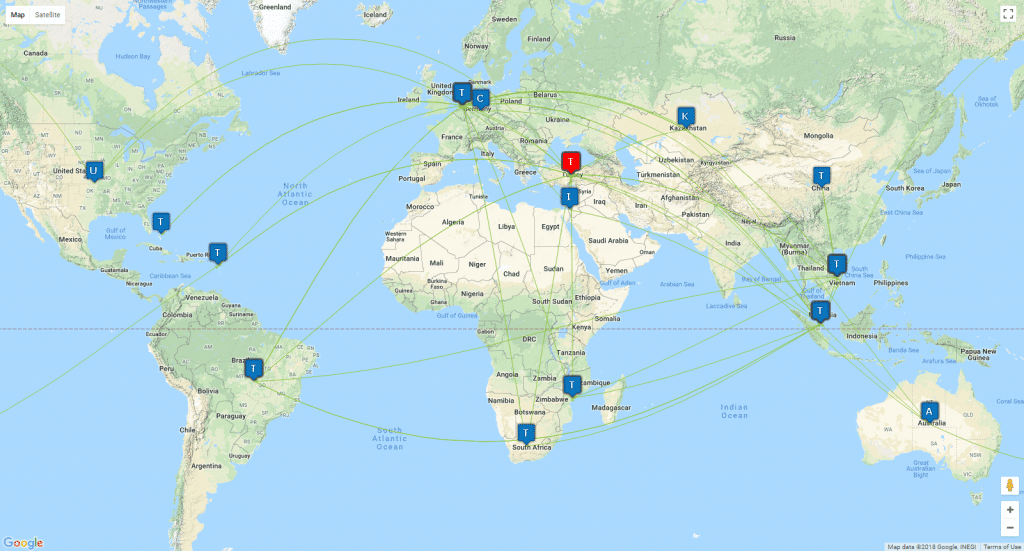

The first step one can take when gaining insight into a supply chain is mapping out your supply chain. But how do you map your supply chain? A visualisation in form of a diagram or a world map is often a simple and effective way in taking this first step. Visualising relationships between you and your suppliers helps you understand your supply chain and identify risks and hotspots.

ChainPoint offers you multiple ways to visualize your supply chain. A literal map, connecting the dots within your supply chain, but also different kinds of visualisation, which we are happy to demonstrate. Supply chain mapping is an intuitive way to gain insight in complex supply chains.

Data quality - the key to mapping

A supply chain manager knows that modern supply chains are getting more and more complex. The supply chains of today consist of hundreds of suppliers all connected to each other in various ways. A supply chain these days is more like a network or a web. Therefore, mapping your chain starts with excellent data quality and ChainPoint’s data management makes sure that your data is of the highest standard.

Our software enables you to:

- Reveal and understand relations between suppliers

- Identify potential risks and hotspots

- Implement corrective measures

- Show impact

- Connect audits and assessments to suppliers

TraceMap - Choose what you see

TraceMap makes it possible to visualise your supply chain from multiple angles, switching easily from upstream to downstream views. In the example on this page, you can see how companies relate to each other and how the different colours identify suppliers. But the possibilities don't end there. It's also possible to use other flows of information via batch numbers or even to add certification statutes.

Built with ChainPoint technology

TraceMap is more than a nice looking tool. The ChainPoint platform will make sure that what you see on screen, is based on reliable and secure data. Every node in TraceMap can be inspected for more information and linked to reports for further analysis.

Mapping your supply chain with secondary data

One of the advantages of supply chain mapping is that you can add all sorts of data. Including data form external sources. We help you utilise publicly available data, about corruption, slavery and conflicts, to visualise risks in your supply chain. Maps immediately reveal which parts of your supply chain are exposed to risks regarding unethical practices or disruption.

Let us show you how it works.

Book a demo

As experts in supply chains, ChainPoint offers a solution for every supply chain there is: from the most straight-forward supply chain to the multi-layered complex web of suppliers spanning multiple tiers and countries.

With ChainPoint software you can easily manage the relationships between you and your suppliers in one system.

If you want more information on mapping or want to request a demo, please fill out the form and we will contact you as soon as possible!